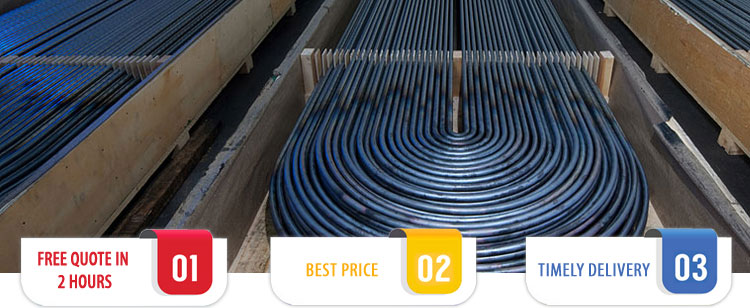

MD Exports LLP Specialized in U - Tube Heat Exchangers Tube, which are manufactured using superior grade of steel like Stainless Steel 304,304L,310,310S,316,316L,317L. These Tubing are most durable and manufactures to fit in different size of Pipes. Engineers & World's Best Project Consultants use these stainless steel Tubing in Machined Components, MD Exports LLP manufacturing U - Tube Heat Exchangers Tube & supplying to Government sector companies since 2 decades,we are approved vendor of U - Tube Heat Exchangers Tube in top notch government sector companies like ONGC, Indian Oil,NTPC,BHEL,ONGC,HPCL BPCL etc.we are also Saudi Aramco approved supplier of U - Tube Heat Exchangers Tube, we have supplied Stainless U - Tube Heat Exchangers Tube to companies involved in Equipment Manufacturing, Mining, Oil Refineries, Chemical manufacturing, Steel and Alloy Steel Manufacturing, Utilities and Transportation, and Industrial Construction We Also Supply & Maintain huge stock of Other Grades of U - Tube Heat Exchangers Tube like Stainless Steel, Alloy Steel Tuberia, Inconel Pipe Tube, Monel Pipe Tube, Hastelloy Pipe Tube, Nickel Pipe Tube, Alloy Steel Pipe Tube, Stainless Steel Seamless Pipes Tube Tubing Tuberia.

MD Exports LLP Specialized in U - Tube Heat Exchangers Tube, which are manufactured using superior grade of steel like Stainless Steel 304,304L,310,310S,316,316L,317L. These Tubing are most durable and manufactures to fit in different size of Pipes. Engineers & World's Best Project Consultants use these stainless steel Tubing in Machined Components, MD Exports LLP manufacturing U - Tube Heat Exchangers Tube & supplying to Government sector companies since 2 decades,we are approved vendor of U - Tube Heat Exchangers Tube in top notch government sector companies like ONGC, Indian Oil,NTPC,BHEL,ONGC,HPCL BPCL etc.we are also Saudi Aramco approved supplier of U - Tube Heat Exchangers Tube, we have supplied Stainless U - Tube Heat Exchangers Tube to companies involved in Equipment Manufacturing, Mining, Oil Refineries, Chemical manufacturing, Steel and Alloy Steel Manufacturing, Utilities and Transportation, and Industrial Construction We Also Supply & Maintain huge stock of Other Grades of U - Tube Heat Exchangers Tube like Stainless Steel, Alloy Steel Tuberia, Inconel Pipe Tube, Monel Pipe Tube, Hastelloy Pipe Tube, Nickel Pipe Tube, Alloy Steel Pipe Tube, Stainless Steel Seamless Pipes Tube Tubing Tuberia.

We stock approximately 1000 tonnes of high quality certified U - Tube Heat Exchangers Tube in numerous sizes and materials which can be packed and shipped to any destination worldwide.

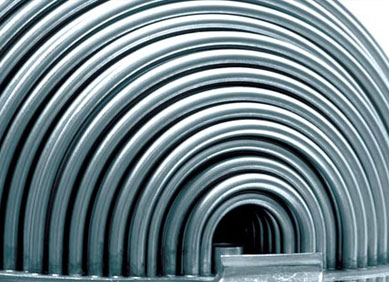

To overcome the shortcoming of complicated structure of floating-head heat exchanger and remain the advantages that the tube bundle of floating-heat exchanger can be pulled out and the thermal stress can be eliminated, U-tube heat exchanger has been developed. U-tube heat exchanger is a kind of heat exchanger whose tubes are bent into U-shape and both ends of the tubes are fixed on the same tube sheet.

1. Advantages of U-tube heat exchanger

1) Simple structure saves a piece of tube sheet and a channel. The manufacturing cost of U-tube heat exchanger is low;

2) The tube bundle and the shell are separated, so they cannot restrain each other and the thermal stress is eliminated when they are heated.

3) The tube bundle can be pulled out from the shell, and the outside tube is cleaned easily.

2. Main disadvantages of U-tube heat exchanger

1) When the tube is bent, a certain radius of curvature must be ensured. So a larger space, whose width is twice as large as the outside diameter of heat transfer tube, exists in the middle part of tube bundle to make the fluid flow the short pass easily, bad for the heat transfer. Therefore, a piece of middle baffle is mounted in the middle of the tube bundle, to prevent the short pass of fluid and improve the heat transfer efficiency.

2) It is hard to clean the inside of tube, so the clean media and the media not easy to scale should flow in the inside of tube.

3) When the tube is damaged to cause the leakage during operation, other tubes cannot be replaced except that the outermost tube of the tube bundle can be replaced. At that time, the leaked tube will be blocked off, to decrease the heat transfer area.

U-tube heat exchanger is generally used in the services with high temperature and high pressure. When the U-tube exchanger is applied at higher pressure, the heat transfer tube with thicker wall should be adopted to compensate the thickness reduction of tube wall caused by bending tube. Some residual stresses remain on the tube wall during the tube bent, so the annealing treatment should be carried out after bending the tube.

Two Pass

MD Exports LLP Two Pass Standardized U-Tube Exchangers have been manufactured to the specifications displayed. Units can be provided in accordance with ASME Sect. VIII, Sect. V, Sect. IX of the Boiler and Pressure Vessel Code, TEMA, API, HEI, and 3 A standards. In addition, our designs can incorporate all your specifications to insure compliance with your plant standards.

Shell O.D. |

Dimensions (inches) |

Nozzles & Fittings (inches) |

|||||||||

| G** | H | K | L* | M | N | A | B | C | D | E | |

| 6 5/8 | 2 | 11 7/8 | 10 3/8 | 4 1/4 | 5 | 8 5/16 | 2 | 2 | 2 | 2 | 3/4 |

| 8 5/8 | 2 | 12 7/8 | 11 1/2 | 4 3/4 | 5 | 9 5/8 | 3 | 3 | 3 | 3 | 3/4 |

| 10 3/4 | 3 | 12 7/8 | 12 1/2 | 5 3/4 | 5 | 10 3/8 | 3 | 3 | 3 | 3 | 3/4 |

| 12 3/4 | 4 | 15 | 14 1/2 | 6 3/8 | 6 | 11 3/8 | 4 | 4 | 4 | 4 | 3/4 |

| 14 | 5 | 18 | 18 5/8 | 6 3/4 | 8 | 12 | 6 | 6 | 6 | 6 | 3/4 |

| 16 | 5 | 18 1/8 | 19 1/4 | 7 3/8 | 8 | 13 | 6 | 6 | 6 | 6 | 3/4 |

| 18 | 5 | 19 1/4 | 21 5/8 | 9 | 9 | 14 | 6 | 6 | 6 | 6 | 3/4 |

| 20 | 5.5 | 21 3/8 | 22 1/8 | 9 5/8 | 9 | 15 | 6 | 6 | 8 | 8 | 3/4 |

| 22 | 5.5 | 23 1/2 | 26 5/8 | 10 1/4 | 11 | 16 | 8 | 8 | 8 | 8 | 3/4 |

| 24 | 5.5 | 23 1/2 | 27 1/8 | 10 3/4 | 11 | 17 | 8 | 8 | 8 | 8 | 3/4 |

| 26 | 5.5 | 24 1/2 | 27 5/8 | 11 1/4 | 11 | 18 | 8 | 8 | 8 | 8 | 1 |

| 28 | 5.5 | 24 5/8 | 28 1/8 | 11 7/8 | 11 | 19 | 8 | 8 | 8 | 8 | 1 |

| 30 | 7 | 28 3/4 | 32 3/4 | 12 1/2 | 13 | 20 | 10 | 10 | 10 | 10 | 1 |

| 32 | 7 | 29 7/8 | 34 1/4 | 13 1/8 | 14 | 21 | 10 | 10 | 10 | 10 | 1 |

| 34 | 9 | 32 | 34 3/4 | 13 3/4 | 14 | 22 | 10 | 10 | 12 | 12 | 1 |

| 36 | 9 | 34 1/8 | 39 3/8 | 14 3/8 | 16 | 23 | 12 | 12 | 12 | 12 | 1 |

| 38 | 10 | 35 1/8 | 39 7/8 | 14 7/8 | 16 | 24 | 12 | 12 | 14 | 14 | 1 |

| 40 | 10 | 36 1/8 | 42 3/8 | 15 1/2 | 17 | 25 | 14 | 14 | 14 | 14 | 1 |

| 42 | 10 | 36 3/8 | 43 | 16 1/8 | 17 | 26 | 14 | 14 | 14 | 14 | 1 |

*L = Tube length + L (from table above)

**G = Tube length + G (from table above)

To find out more about our U - Tube Heat Exchangers Tube, and get more information please fill enquiry form and one of our sales representatives will contact you.

To find out more about our U - Tube Heat Exchangers Tube, and get more information please fill enquiry form and one of our sales representatives will contact you.

Products : Alloy Steel, Stainless Steel,Seamless Pipes Tube Tubing Tuberia, ASTM A213/A213M Seamless Tubes, ASTM A269 / A269M Seamless Tubes, ASTM A511 / A511M Seamless Tubes, Seamless Steel Pipe, Cold Drawn Steel Pipes Seamless Tube, Hot Rolled Steel Pipes Seamless Tube, Hot Expanded Pipes Seamless Tube, API 5L Pipes (Seamless Steel Pipes), Seamless Boiler Steel Pipes, Seamless Structural Steel Pipes

Industry We Serve Inconel Pipe Tube, Monel Pipe Tube, Hastelloy Pipe Tube, Nickel Pipe Tube, Alloy Steel Pipe Tube and Stainless Steel Seamless Pipes Tube Tubing Tuberia Supplied Architectural & General Engineering, Automobiles Industry, Breweries & Distilleries Industry, Cement Industry, Chemicals Industry, Dairy & Food Processing Industry, Fertilizers Industry, Heat Exchangers Industry, Oil Companies, Petrochemicals & Refineries, Power & Nuclear Energy / Atomic Energy, Railway Industry, Ship Building Industry, Solvent & Pulp Industry, Submersible Pumps Industry, Sugar Industry, Textile Machinery & Processing Houses etc..

Find Our Dealers are in below countries:

|| Products Matching Your Requirements ||

Engineers also search below grades pipe/ tube

WE ARE SPECIALIST

Products

- ---- TYPES OF TUBES ----

- SURPLUS TUBING

- NEW TUBING

- SEAMLESS TUBING

- CONDENSER & HEATER TUBES

- WELDED & TUBES

- EFW (ELECTRIC FUSION WELDED) TUBE

- INSTRUMENTATION TUBE

- HEAT EXCHANGER TUBES

- HEAT EXCHANGER ‘U’-TUBES

- COILED TUBING

- CAPILLARY TUBE

- HOT FINISHED SEAMLESS STEEL TUBING

- COLD DRAWN SEAMLESS STEEL TUBING

- DRAWN OVER MANDREL (DOM) STEEL TUBING

- ELECTRIC RESISTANCE WELDED (ERW) STEEL TUBING

Types of Pipes

Materials

- Inconel ®

- Monel ®

- Hastelloy ®

- Nickel ®

- Alloy Steel

- API 5L Line Pipe

- Carbon Steel

- Duplex / Super Duplex Steel

- Stainless Steel

|

Clients' TestimonialsWhy us?

|