Best Quality Steel Pipes !! Genuine Suppliers of Zenith Hollow Pipes, Look Up Quick Results Now!, Better Deal On Bulk Zenith Hollow Pipes., Supplier of Zenith Hollow Pipes India, Call us Now & Get Free Estimates!

Zenith Hollow Pipes Dealers UAE. Zenith Hollow Pipes Dealers Qatar, Zenith Hollow Pipes Dealers Kuwait, Zenith Hollow Pipes Dealers IRAN, Zenith Hollow Pipes Dealers Saudi Arab , Zenith Hollow Pipes Dealers Indonesia, Zenith Hollow Pipes Dealers Russia

ISO 9001:2008 Certified Company ( 37 Years Old ) MD Exports LLP is No. 1 Distributor and Dealer of Zenith Steel Hollow Section Pipe

ISO 9001:2008 Certified Company ( 37 Years Old ) MD Exports LLP is No. 1 Distributor and Dealer of Zenith Steel Hollow Section Pipe

|| Brand Products Matching Your Requirements ||

Engineers Also Search Below Brands Pipes & Tubes

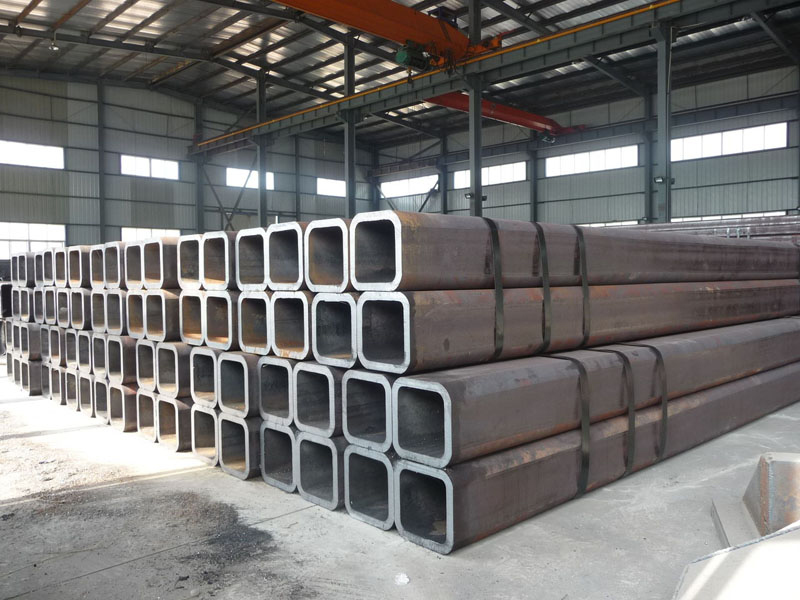

Zenith Hollow Sections Pipes

Hollow Sections Manufacturing Process

Hollow section is formed from hot-rolled coil produced in steel mill. All the incoming coils are verified based on the test certificate received from steel mill for their chemistry and mechanical properties.

The forming stage of Hollow Section begins with a single-width strip. The width of strip is roughly equal to the perimeter of the pipe to be produced. The edges of coil are sheared to pre-specified widths in slitting line.

The process involves uncoiling & leveling of coils and processing the same. The lead end of each coil is squared by shearing operation for threading into the mill. Then this end is joined with coil end of outgoing coil to maintain continuity in production and reduce losses.

To maintain continuity of production, it is accumulated in an accumulator/loop pit. It is then gradually and continuously formed into a circular shape by shaped rolls as per the required diameter in forming stands arranged in tandem. In the welding stand, edges of formed strip are pre heated by High Frequency Electrical Induction heating process to the desired temperature, which are mechanically pressed together horizontally to form continuous weld seam. This welding process does not need any filler metal. Instead, the welding pressure causes some of the metal to be squeezed from the joint, forming a bead of metal on inside and outside of the tube. This bead or welding flash is trimmed during the  process. The weld seam is examined and adjusted as per the weld parameters, including temperature and outside diameters. Subsequently pipe string passes through shaping stands to produce square or rectangular section before it is cut to required length as per customer's requirement or relevant specification.

process. The weld seam is examined and adjusted as per the weld parameters, including temperature and outside diameters. Subsequently pipe string passes through shaping stands to produce square or rectangular section before it is cut to required length as per customer's requirement or relevant specification.

During production, online visual inspection is also carried out. Deburring of all the sections are carried out. All sections are marked and/or paint stenciled as per the order requirements, packed in bundles before shifting in the storage yard. Sections are then loaded on trailers or trucks and dispatched to the customer's site. These sections can also be supplied with black paint/oiling as per customer's requirements.

Applications of Hollow Sections

Agricultural implement frames

Amusement park and equipments

Automobile chassis

Bridges

Bus stands

Conveyor gantries, trestles

Cranes

Drilling rigs

Exhibition stalls

Furniture, partition frames

Guard rails, staircases

Industrial lifting equipment

Industrial sheds

Large span portal frame

Material storage racks

Mine roof support system

Pallets

Pedestrian walkover (foot over bridge)

Sign supporting structure

Space frames

Sports galleries

Transmission line tower

Trolleys

Truck and bus body members

Trusses, columns and purlins etc

Product Range of Hollow Sections

| Rectangular Hollow Sections | Square Hollow Sections | |||

| Size (mm x mm) | Thickness (mm) | Size (mm x mm) | Thickness (mm) | |

| 50 X 25 | 1.60 | 25 X 25 | 1.60 | |

| 2.00 | 2.00 | |||

| 2.60 | 2.60 | |||

| 3.20 | 2.90 | |||

| 4.00 | 3.20 | |||

| 4.50 | 4.00 | |||

| 60 X 40 | 1.60 | 4.50 | ||

| 2.00 | 32 X 32 | 1.60 | ||

| 2.60 | 2.00 | |||

| 3.20 | 2.60 | |||

| 4.00 | 2.90 | |||

| 4.50 | 3.20 | |||

| 66 x 33 | 1.60 | 4.00 | ||

| 2.00 | 4.50 | |||

| 2.60 | 38 X 38 | 1.60 | ||

| 3.20 | 2.00 | |||

| 4.00 | 2.60 | |||

| 4.50 | 2.90 | |||

| 80 x 40 | 1.60 | 3.20 | ||

| 2.00 | 4.00 | |||

| 2.60 | 4.50 | |||

| 3.20 | 40 X 40 | 1.60 | ||

| 4.00 | 2.00 | |||

| 4.50 | 2.60 | |||

| 80 X 60 | 1.60 | 2.90 | ||

| 2.00 | 3.20 | |||

| 2.60 | 4.00 | |||

| 3.20 | 4.50 | |||

| 4.00 | 50 X 50 | 1.60 | ||

| 4.50 | 2.00 | |||

| 96 X 48 | 1.60 | 2.60 | ||

| 2.00 | 2.90 | |||

| 2.60 | 3.20 | |||

| 3.20 | 3.60 | |||

| 4.00 | 4.50 | |||

| 4.50 | 60 X 60 | 1.60 | ||

| 122 X 61 | 1.60 | 2.00 | ||

| 2.00 | 2.60 | |||

| 2.60 | 2.90 | |||

| 3.20 | 3.20 | |||

| 4.00 | 4.00 | |||

| 4.50 | 4.50 | |||

| 120 X 60 | 1.60 | 72 X 72 | 1.60 | |

| 2.00 | 2.00 | |||

| 2.60 | 2.60 | |||

| 3.20 | 2.90 | |||

| 4.00 | 3.20 | |||

| 4.50 | 4.00 | |||

| 145 X 82 | 1.60 | 4.80 | ||

| 2.00 | 80 X 80 | 1.60 | ||

| 2.60 | 2.00 | |||

| 3.20 | 2.60 | |||

| 4.00 | 2.90 | |||

| 4.50 | 3.20 | |||

| 150 X 100 | 1.60 | 4.00 | ||

| 2.00 | 4.50 | |||

| 2.60 | 91.5 X 91.5 | 1.60 | ||

| 3.20 | 2.00 | |||

| 4.00 | 2.60 | |||

| 4.50 | 2.90 | |||

| 5.40 | 3.20 | |||

| 172 X 92 | 1.60 | 4.00 | ||

| 2.00 | 4.50 | |||

| 2.60 | 100 X 100 | 1.60 | ||

| 3.20 | 2.00 | |||

| 4.00 | 2.60 | |||

| 4.50 | 2.90 | |||

| 5.40 | 3.20 | |||

| 200 X 100 | 3.20 | 4.00 | ||

| 4.00 | 4.50 | |||

| 5.00 | 113.5 X 113.5 | 1.60 | ||

| 6.00 | 2.00 | |||

| 7.00 | 2.60 | |||

| 8.00 | 2.90 | |||

| 220 X 140 | 3.20 | 3.20 | ||

| 4.00 | 4.00 | |||

| 5.00 | 4.50 | |||

| 6.00 | 132 X 132 | 2.00 | ||

| 7.00 | 2.60 | |||

| 8.00 | 3.20 | |||

| 240 X 120 | 3.20 | 4.00 | ||

| 4.00 | 4.50 | |||

| 5.00 | 5.40 | |||

| 6.00 | 150 X 150 | 2.00 | ||

| 7.00 | 2.60 | |||

| 8.00 | 3.20 | |||

| 9.00 | 4.00 | |||

| 10.00 | 4.50 | |||

| 260 X 180 | 3.20 | 5.00 | ||

| 4.00 | 6.00 | |||

| 5.00 | 7.00 | |||

| 6.00 | 180 X 180 | 2.60 | ||

| 7.00 | 3.20 | |||

| 8.00 | 4.00 | |||

| 9.00 | 4.50 | |||

| 10.00 | 5.00 | |||

| 300 X 150 | 3.20 | 6.00 | ||

| 4.00 | 7.00 | |||

| 5.00 | 8.00 | |||

| 6.00 | 220 X 220 | 2.60 | ||

| 7.00 | 3.20 | |||

| 8.00 | 4.00 | |||

| 9.00 | 4.50 | |||

| 10.00 | 5.00 | |||

| 300 X 200 | 4.00 | 6.00 | ||

| 5.00 | 7.00 | |||

| 6.00 | 8.00 | |||

| 7.00 | 250 X 250 | 2.60 | ||

| 8.00 | 3.20 | |||

| 9.00 | 4.00 | |||

| 10.00 | 4.50 | |||

| 5.00 | ||||

| 6.00 | ||||

| 7.00 | ||||

| 8.00 | ||||

To find out more about our Zenith Steel Hollow Section Pipe, and get more information please fill enquiry form and one of our sales representatives will contact you.

To find out more about our Zenith Steel Hollow Section Pipe, and get more information please fill enquiry form and one of our sales representatives will contact you.

Industry We Serve Inconel Pipe Tube, Monel Pipe Tube, Hastelloy Pipe Tube, Nickel Pipe Tube, Alloy Steel Pipe Tube and Stainless Steel Seamless Pipes Tube Tubing Tuberia Supplied Architectural & General Engineering, Automobiles Industry, Breweries & Distilleries Industry, Cement Industry, Chemicals Industry, Dairy & Food Processing Industry, Fertilizers Industry, Heat Exchangers Industry, Oil Companies, Petrochemicals & Refineries, Power & Nuclear Energy / Atomic Energy, Railway Industry, Ship Building Industry, Solvent & Pulp Industry, Submersible Pumps Industry, Sugar Industry, Textile Machinery & Processing Houses etc..

Find Our Dealers are in below countries:

|| Brand Products Matching Your Requirements ||

Engineers Also Search Below Brands Pipes & Tubes

WE ARE SPECIALIST

ORIGIN MATERIAL We Have

- Tata Steel

- Essar Steel

- Arcelor Mittal

- Sosta Stainless Pipes

- ARVIND PIPES TUBES

- ISMT Ltd

- Tata Tubes

- Tata Structura

- inox tech pipes

- Kobe steel Pipes

- Maharashtra Seamless Ltd (MSL)

- Jindal Star Pipe

- Jindal Saw Ltd.

- Jindal Steel Jpl Pipe

- Nippon Steel (Sumitomo Metals)

- Ratnamani Metals Tubes Ltd

- Remi Group Remi Steel Pipes

- Sandvik Materials Technology

- Sanyo Special Steel Pipes

- Suraj Limited

- Tenaris pipes

- Tubacex Pipes

- DMV Stainless Pipe

- Seah Steel - South Korea

- Mukat Pipes Limited

- Lalit Pipes and Pipes Limited

- Man Industries India Limited

- EEW – SOUTH KOREA

- Eisenbau Kraemer GERMANY

- Lloyds Line Pipes Limited (LLPL)

- zenith steel pipes zenith birla Limited

- ESW PIPE – GERMANY

Materials

- Inconel ®

- Monel ®

- Hastelloy ®

- Nickel ®

- Alloy Steel

- API 5L Line Pipe

- Carbon Steel

- Duplex / Super Duplex Steel

- Stainless Steel

- Duplex / Super Duplex

- Carbon Steel

|

Clients' TestimonialsWhy us?

|