Best Quality Steel Pipes !! Genuine Suppliers of Zenith Spiral Pipes, Look Up Quick Results Now!, Better Deal On Bulk Zenith Spiral Pipes., Supplier of Zenith Spiral Pipes India, Call us Now & Get Free Estimates!

Zenith Spiral Pipes Dealers UAE. Zenith Spiral Pipes Dealers Qatar, Zenith Spiral Pipes Dealers Kuwait, Zenith Spiral Pipes Dealers IRAN, Zenith Spiral Pipes Dealers Saudi Arab , Zenith Spiral Pipes Dealers Indonesia, Zenith Spiral Pipes Dealers Russia

ISO 9001:2008 Certified Company ( 37 Years Old ) MD Exports LLP is No. 1 Distributor and Dealer of Zenith Steel Spiral Pipes

ISO 9001:2008 Certified Company ( 37 Years Old ) MD Exports LLP is No. 1 Distributor and Dealer of Zenith Steel Spiral Pipes

|| Brand Products Matching Your Requirements ||

Engineers Also Search Below Brands Pipes & Tubes

Zenith Spiral Pipes

Spiral Pipes Manufacturing

Introduction

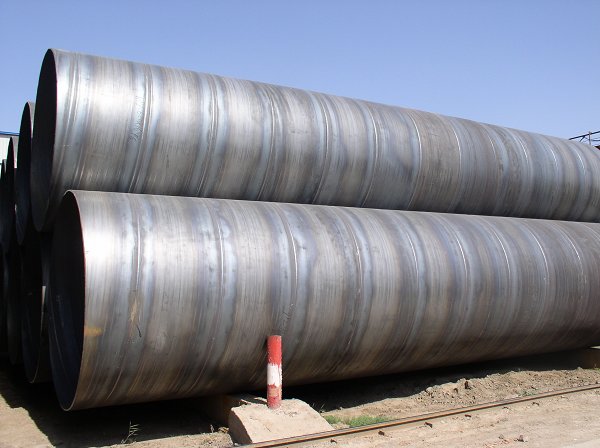

Our manufacturing facility for helical submerged arc welded (HSAW) pipes employing electrical fusion welding is a state of

the art facility to produce quality pipes. The spiral welded pipe mill is BYARD SPIRALMILL sdn. Bhd. make, along with the

other equipments provide the company with the superior technology and competent to deal with the best in the industry.

The pipe plant has a capacity to produce 70,000 MT of pipe per annum and can produce spirally welded pipes in the range of 18

inches (457 mm) to 100 inches (2540 mm) with maximum wall thickness of 1 inch (25.4 mm) & pipe length of 6 meters to 13

meters as per client’s requirement confirming to various national as well as international quality standards.

The uniqueness of our plant is that the whole unit is mobile & can be moved to the project site. This feature benefit our clients not only by reducing the transportation cost of pipes but it reduces the damage of pipes during transportation & also helps timely execution of the project by continuous & dedicated supply of pipes for the particular project.

Spiral Pipes Manufacturing Process

Spiral pipes are produced from hot rolled coils produced in steel plant. All the incoming coils are verified for its chemistry &

mechanical properties as per the test certificate received from the steel plant tomeet specification requirements.

The Spiral Pipe manufacturing process involves setting of the mill entry line as per the calculated angle with respect to centre

line of pipe & forming cage to the required diameter. The coils are opened, leveled in leveler & end sheared to facilitate

joining of incoming & outgoing coils & joined by Submerged Arc Welding to maintain production continuity. Subsequently

it is guided & its edges are milled to get the desired edge. It is then formed at the forming table on the principle of three roll

bending to get the required diameter & auto SAW welded from inside. Since the strip is being fed continuously inside welding operation is also continuous. At about 180 degree phase, continuous outside auto SAW welding is carried out so that string of formed pipe is welded from both sides. It is then cut to the required length by Plasma equipment at the cut off equipment. Individual pipe is serially numbered for its traceability. During forming & welding, weld gap at inside welding is maintained by gap control unit to get adequate fusion from inside.

All the pipes are then inspected from inside as well as outside to find defect in the weld or body, diameter, forming defects etc. Pipes requiring rectification are manually rectified by manual welding &/or grinding depending on the nature of defect. Pipe ends are then beveled. Each pipe is then hydrostatically tested as per the calculated pressure; it is then inspected before offering to the customer’s inspectors. Accepted pipes are then paint stenciled as per the requirement before shifting it to the storage yard & subsequent dispatch.

Advantages of Spiral Pipes over Site Fabricated Pipes

Spiral pipes are manufactured continuously from hot rolled steel coils & hence length of pipes can be maintained

as per the customer’s requirement from 6 to 13 meters or more. However, fabricated pipes are 2 to 2.5 meters in length.

Thus resulting into higher number of joints per kilometer of pipeline which results in higher lead time for laying the pipeline.

Higher laying cost due to increased number of joints.

Higher probability of leakages at joints.

Higher maintenance cost.

Dimensional accuracy i.e. Thickness Uniformity, Ovality, Straightness & diameter control is excellent in case of spiral pipes rather than manually bent & fabricated pipes at site.

Spiral pipes has uniform round periphery as against peaks at weld joints in case of site fabricated pipes.

Bursting pressure acts at a right angle to the axis of the pipe. Since, welds of spiral pipes are at an angle, these weld joints withstand higher bursting pressure as against longitudinal welds of the site fabricated pipes; hence spiral pipes can handle water hammer effect smoothly.

Spiral SAW pipe shows better weld strength than the basic raw material as against site fabricated pipes.

Spiral pipe manufacturing has automatic weld gap control arrangement; hence it gives better control of

weld parameters & quality.

In case of pipeline bursting due to material failure, the spiral weld seam acts as a crack propagation arrester.

Delivery of spiral pipes is much faster than site fabricated pipes.

Product Range of Spiral Pipes

Product Range of Spiral Pipes

We can manufacture Spirally Welded SAW Pipes in the following range:

Pipe Diameter: 18" to 100"

Thickness: 5.5 mm to 25.4 mm

Length: As per customer's requirement (Maximum upto 13 meters)

Capacity: 70,000 MT / Annum

Applications of Spiral Pipes

Transportation of raw & potable Water

Transportation of Oil & Gas

Transportation of Sewage disposal

Irrigation

Piling

Ash / Slurry Transportation

To find out more about our Zenith Steel Spiral Pipes, and get more information please fill enquiry form and one of our sales representatives will contact you.

To find out more about our Zenith Steel Spiral Pipes, and get more information please fill enquiry form and one of our sales representatives will contact you.

Industry We Serve Inconel Pipe Tube, Monel Pipe Tube, Hastelloy Pipe Tube, Nickel Pipe Tube, Alloy Steel Pipe Tube and Stainless Steel Seamless Pipes Tube Tubing Tuberia Supplied Architectural & General Engineering, Automobiles Industry, Breweries & Distilleries Industry, Cement Industry, Chemicals Industry, Dairy & Food Processing Industry, Fertilizers Industry, Heat Exchangers Industry, Oil Companies, Petrochemicals & Refineries, Power & Nuclear Energy / Atomic Energy, Railway Industry, Ship Building Industry, Solvent & Pulp Industry, Submersible Pumps Industry, Sugar Industry, Textile Machinery & Processing Houses etc..

Find Our Dealers are in below countries:

|| Brand Products Matching Your Requirements ||

Engineers Also Search Below Brands Pipes & Tubes

WE ARE SPECIALIST

ORIGIN MATERIAL We Have

- Tata Steel

- Essar Steel

- Arcelor Mittal

- Sosta Stainless Pipes

- ARVIND PIPES TUBES

- ISMT Ltd

- Tata Tubes

- Tata Structura

- inox tech pipes

- Kobe steel Pipes

- Maharashtra Seamless Ltd (MSL)

- Jindal Star Pipe

- Jindal Saw Ltd.

- Jindal Steel Jpl Pipe

- Nippon Steel (Sumitomo Metals)

- Ratnamani Metals Tubes Ltd

- Remi Group Remi Steel Pipes

- Sandvik Materials Technology

- Sanyo Special Steel Pipes

- Suraj Limited

- Tenaris pipes

- Tubacex Pipes

- DMV Stainless Pipe

- Seah Steel - South Korea

- Mukat Pipes Limited

- Lalit Pipes and Pipes Limited

- Man Industries India Limited

- EEW – SOUTH KOREA

- Eisenbau Kraemer GERMANY

- Lloyds Line Pipes Limited (LLPL)

- zenith steel pipes zenith birla Limited

- ESW PIPE – GERMANY

Materials

- Inconel ®

- Monel ®

- Hastelloy ®

- Nickel ®

- Alloy Steel

- API 5L Line Pipe

- Carbon Steel

- Duplex / Super Duplex Steel

- Stainless Steel

- Duplex / Super Duplex

- Carbon Steel

|

Clients' TestimonialsWhy us?

|